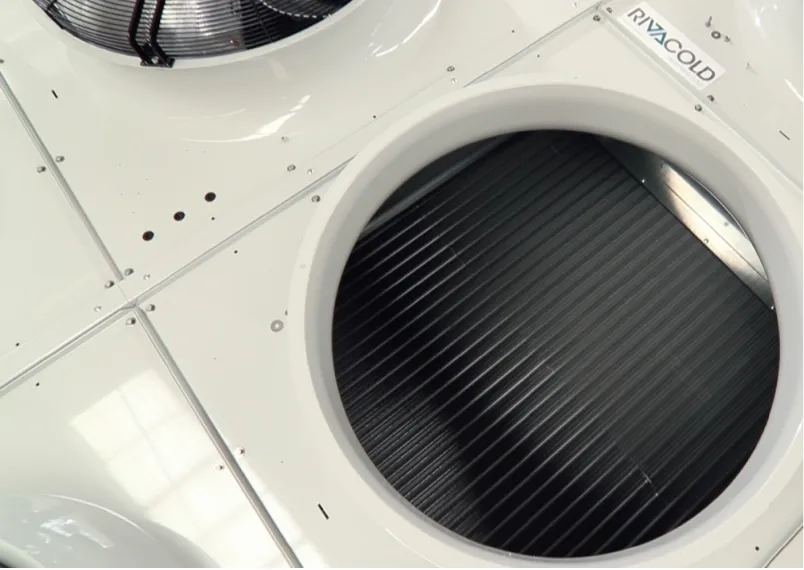

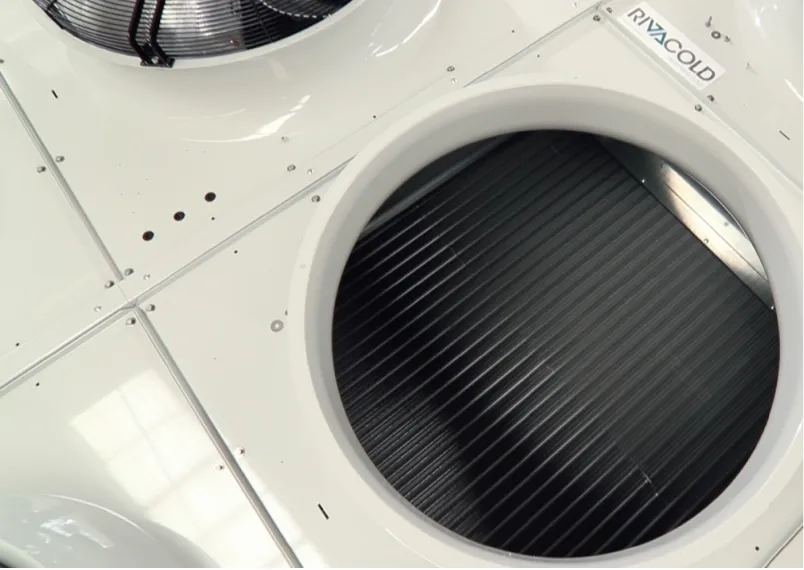

THE VRL LABORATORY

The VRL laboratory, created in collaboration with the “Università Politecnica delle Marche”, is an innovative technology center in Europe for R&D in the field of refrigeration: 15 ENGINEERS AND TECHNICIANS. 750 TESTS FOR A TOTAL OF 15,000 HOURS PER YEAR. ANY ENVIRONMENTAL CONDITION CAN BE SIMULATED: OPERATING TEMPERATURES FROM -45°C TO +55°C.

Designed and developed jointly with the Università Politecnica delle Marche, the Vag Refrigeration Laboratory is a state-of-the-art technology center that represents a unique facility in Europe for research and development in the world of refrigeration technology

Lab 1

Lab 1

×

Lab 2

Lab 2

×

Lab 3

Lab 3

×

Lab 4

Lab 4

×

Lab 5

Lab 5

×

- EN ISO 23953-2: Refrigerated cabinets to display and sell foodstuffs

- EN 16825 / EN ISO 22041: Refrigerated storage cabinets and counters for professional use

- EN17032 / EN ISO 22042: Blast chillers and freezers cabinets for professional use

- EN 62552 1-2-3: Household refrigerating appliances

- EN 16901 / EN ISO 22043: Ice-cream freezers

- EN 16902 / EN ISO 22044: Commercial beverage coolers

- EN 50597 / EN IEC 63252: Energy consumption for vending machines

Lab 6

Lab 7

Lab 7

×

Lab 8

Lab 8

×

Meaning of accreditation

Accreditation guarantees the competence, independence and neutrality of the certification, inspection and testing bodies as well as the testing laboratory. In addition, it ensures the ability to assess the legality of goods and services according to the voluntary and mandatory rules.

Accredia is the competent body appointed by the Italian government to certify the competence, independence and neutrality of the bodies and laboratories.

As an impartial authority, Accredia guarantees the reliability of the work of institutions and laboratories that provide a service in the public interest.

Accreditation ensures that the certification, inspection and testing bodies as well as the testing laboratories meet all the requirements of the standards. Accreditation is carried out worldwide in accordance with the international standard ISO/IEC 17011. In the European Union, European Regulation 765/2008 stipulates that each Member State must designate the competent national authority and give this activity legal status for the first time, as it is a public authority.

In Italy, Accredia is the only competent body designated by the government.